OVENS

Elevated Cure Oven

The elevated oven design saves valuable floor space. This space can be used for the dry-off oven or for cooling the parts prior to powder coating or prior to unloading, depending on the configuration of the system. This type of oven has bottom entry/exit openings which is the simplest and most effective type of air seal. This oven allows parts to enter/exit the oven through openings in the oven floor. Because it takes advantage of the fact that hot air rises, additional powered devices are not required and a natural heat seal is provided. Roof mounted ovens provide the same advantages.

Radiant-Convection Cure Oven

This oven is complete with our patented gas fired "X-Trad Radiant™ burners as the heat source. The radiant burner provides medium wavelength infrared curing but also curing with convection heat. This combination provides excellent paint and powder curing. This oven provides:

- High efficiency X-Trad Radiant burners, 96% combustion

- Burner output variable from 6,000 BTU to 30,000 BTU

- Faster curing times

- Smaller oven

- Reduced operating cost for gas

- Reduced operating cost for electric

Dual Fuel Bake Oven

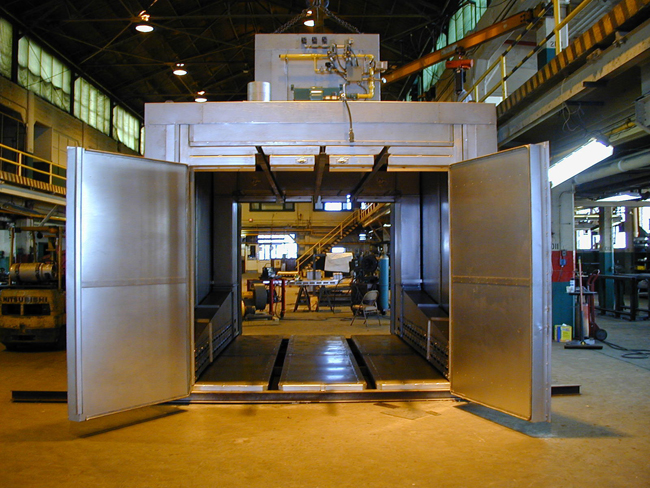

Batch Oven

A batch system is defined as a system that requires the part to be stationary during the washing, dry-off, coating, and curing operations. Batch ovens are typically used to dry/cure parts that are low volume or parts that are too large to be put through a conventional conveyorized system. Parts are loaded onto carts or hung from overhead conveyor rails. Parts are in the oven for a predetermined period of time.

Combination Dry-Off And Cure Oven

The most common combination system is one where the dry-off oven and cure oven are located right next to each other so that they share a common wall. Each oven still has its own heater, controls, and exhaust equipment just as if two individual ovens were present. Amiberica takes this design a step further to save our customers on fuel costs. Only the cure oven is provided with a heat source. When the temperature controller on the dry-off oven calls for more heat, the motorized damper in the ductwork between the two ovens opens and provides heat for the dry-off oven.